Resin-infused boat hulls offer unmatched strength, precision, and performance offshore. By using vacuum pressure to fully saturate dry laminates, this method creates stiffer, more consistent structures, built for serious sportfishing in demanding bluewater conditions.

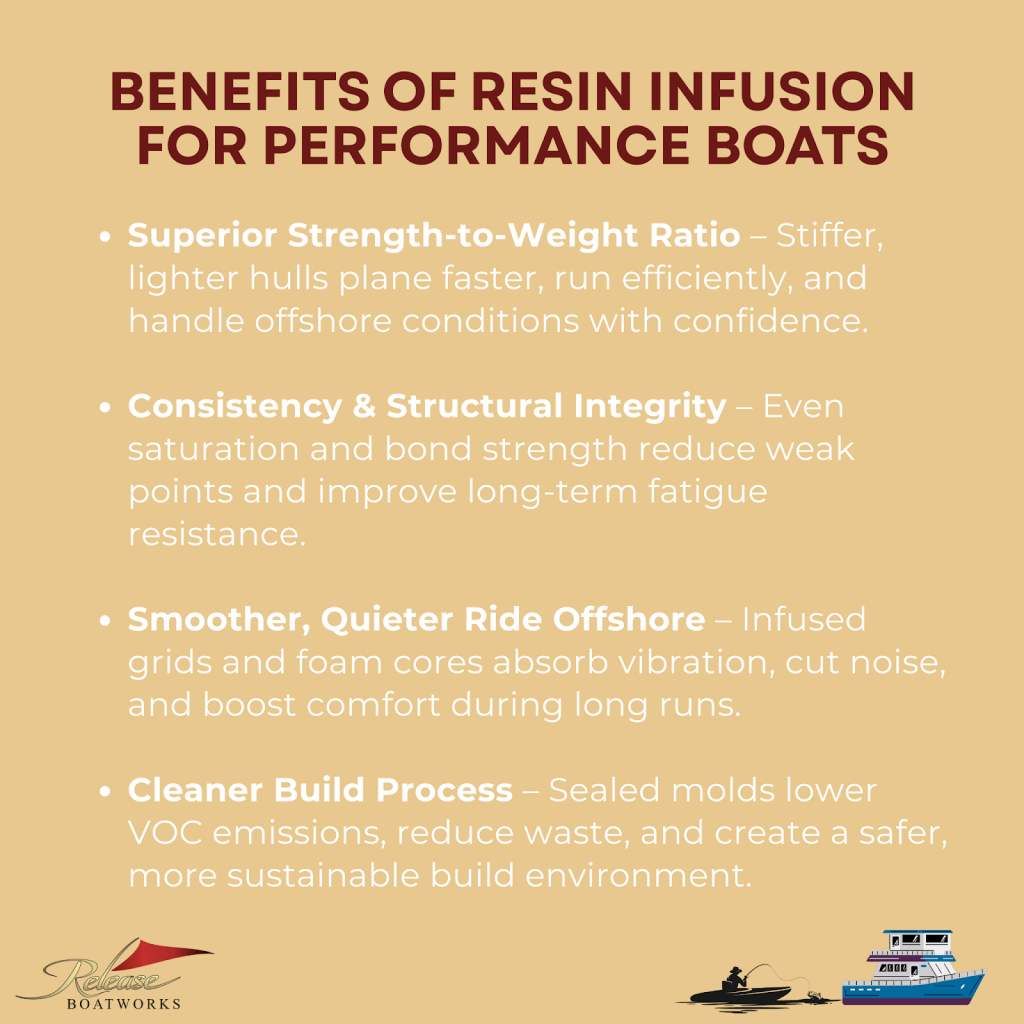

Before getting into the technical breakdown, here are the key advantages resin infusion brings to high-performance sportfish builds:

- Superior Strength-to-Weight Balance for efficient planing and longer range

- Consistent Laminate Quality with fewer weak points and greater longevity

- Smoother, Quieter Ride due to vibration-dampening stringer grids and core materials

- Cleaner Build Process with reduced waste and lower VOC emissions

- Higher Resale Potential through blister-resistant, fully composite construction

At Release Boatworks, every hull we build, from agile express models to long-range gameboats, uses a full resin infusion process. It’s a commitment to offshore performance, reliability, and fishability.

Keep reading to see how this construction method stacks up against traditional techniques, and why it matters when your next run is measured in miles, not minutes.

How Resin Infusion Works – Step by Step

Every stage of the infusion process, from prepping the mold to final cure, affects the strength, consistency, and performance of the hull. Here’s how it works at Release Boatworks, and why each step plays a critical role in building a sportfisher that holds up offshore.

1. Mold Preparation and Surface Treatment

It begins with the mold. Whether we’re building a 43 Walkaround or a 66 Gameboat, a polished, dimensionally accurate mold ensures clean lines, smooth part release, and gelcoat integrity that lasts. Each surface is carefully treated to prevent voids or imperfections in the laminate.

CNC tooling may help, but what truly matters is precision. Our team blends traditional hands-on craftsmanship with modern technology to maintain exacting tolerances throughout the build.

2. Laying Down Dry Laminate & Core Materials

Next is the dry layup: a layered combination of fiberglass with composite core materials like Airex foam. These cores are chosen for durability without unnecessary weight. Each section of the hull, from keel to hullsides to stringer caps, is tailored to the stresses it will face offshore.

We optimize laminate zones based on structural loads, ride quality, and how the boat will be used, whether backing down on a fish, rigging from the cockpit, or pushing through chop. That’s part of what makes the 46 Walkaround so effective: structure designed around real-world use.

3. Bagging the Laminate Under Vacuum

Once the dry stack is in place, the entire layup is sealed beneath a vacuum bag. At this stage, attention to detail is critical. Every edge and flange must hold vacuum integrity. Poor sealing can lead to dry spots or weak bonds that show up later under stress.

We maintain strict pressure monitoring throughout. The result is a consistent, airtight seal, essential for a clean infusion with no surprises.

4. Injecting the Resin

With vacuum pressure holding, resin flows through spiral lines and flow media to saturate the entire laminate. This ensures complete, even distribution, without air pockets or over-saturation.

We use modified epoxy resin throughout our builds. It offers the ideal combination of flexibility, structural reliability, and resistance to blistering, especially critical in high-load applications like the 43 Gameboat.

Infusion demands precision, planning, and execution. Anything less becomes a weak point offshore, and that’s not acceptable in our builds.

5. Curing, Cooling, and Post-Cure Processing

Once the resin sets, the hull is left to cure fully within the mold until it’s structurally stable. After cooling, it’s carefully released, trimmed, and prepared for next-phase work, like bulkhead installation and grid bonding.

Stringers are vacuum-infused as part of the hull for maximum stiffness. This step helps eliminate long-term flex or fatigue and ensures the boat holds together during extended offshore use.

Every step is designed to deliver a hull that runs true, tracks clean, and takes the punishment offshore sportfishing demands.

Benefits of Resin Infusion for Sportfishing & Performance Boats

For offshore anglers who judge quality by performance offshore, not interior square footage, the advantages of resin infusion go well beyond the sales pitch. This isn’t about marketing. It’s about hulls that run cleaner, fish harder, and hold up under real offshore pressure.

Superior Strength-to-Weight Ratio

Resin infusion removes excess resin while ensuring complete saturation of every laminate layer. The result is a stiffer, more efficient hull that planes faster and performs better at cruise. That matters when you’re pushing 100 miles offshore for pelagics or returning at speed after lines out.

We apply this method across the lineup, from the 36 Express to the 55 Flybridge-Walkaround, delivering consistent performance and efficiency across every build.

Consistency & Structural Integrity

Unlike hand lay-up, which varies depending on the builder, resin infusion applies uniform pressure and saturation throughout the structure. That consistency creates better fatigue resistance and fewer weak points, critical in bluewater conditions.

Owners often ask how infused hulls hold up long-term. With composite cores and closed-cell foam in key areas, the answer is simple: they outperform conventional builds, especially after years in saltwater.

Smoother, Quieter Ride Offshore

Infused stringer systems and foam-cored decks reduce hull slap, absorb vibration, and eliminate structural rattle. The result is a quieter, more focused ride, especially when backing down on a fish or maneuvering tight in tournament conditions.

You’ll feel the advantage running a 46 Gameboat at speed or positioning a 55-footer when it’s time to close the deal.

Cleaner Build Process with Fewer VOCs

Resin infusion is more controlled. Closed molds and sealed systems reduce waste and lower VOC emissions. It makes the shop cleaner and the build process more responsible, something serious owners notice, even if it doesn’t show up in a spec sheet.

Better Longevity, Higher Resale

No wood. No rot. No structural guesswork. Infused hulls built with modified epoxy resist delamination, blistering, and soft spots. For owners who plan to run hard and expect their investment to hold value, this level of durability pays dividends over time.

Resin Infusion vs Hand Lay-Up and Vacuum Bagging

There’s no shortage of opinions in boatbuilding. But when it comes to offshore performance, real-world results matter more than theory. Resin infusion offers measurable advantages over traditional methods, especially when speed, strength, and repeatability count.

Performance & Structural Comparison

Hand lay-up is labor-intensive and prone to inconsistencies: air voids, resin pooling, and uneven saturation. Vacuum bagging adds pressure, but lacks full resin control across the entire laminate.

Resin infusion applies controlled pressure and precise resin flow, delivering an optimized resin-to-glass ratio with repeatable structural integrity.

This difference shows up where it counts. Whether you’re pushing a 43 Walkaround through challenging sea states or spinning on a sailfish pack, the hull must stay tight, track cleanly, and respond predictably without flex or fatigue.

Cost, Efficiency & Builder Discipline

Infusion requires precision, controlled tooling, sealed molds, and dedicated time. While it’s not the cheapest path, it reduces resin waste, improves laminate consistency, and speeds up repeatable quality.

That’s why we’re able to deliver in 8–9 months while others quote timelines of several years. Build speed alone means little, but combining efficiency with deep build discipline creates boats that are both fast to build and built right.

Trusting the Builder

Some builders use “infusion” as a marketing label. The real question is how far the process goes.

Are the stringers infused?

Are the bulkheads and grids vacuum-bonded? Is resin flow fully mapped and controlled?

We believe trust starts with transparency. Every infused Gameboat, Walkaround, and Flybridge-Walkaround that leaves our yard reflects that commitment, built from the laminate schedule up for offshore results.

Why Custom Builders Like Us Use Resin Infusion

Resin infusion has nothing to do with trends. It’s about delivering the performance, durability, and fishability serious anglers demand. When you’re building for offshore, not showroom traffic, you engineer boats to earn their place in the spread.

Faster Builds with Better Control

Our resin infusion process allows us to deliver fully custom boats in 8–9 months without compromising craftsmanship. Closed-mold infusion gives tighter control over hull layup, bulkhead bonding, and structural uniformity, cutting down on delays and rework.

This is how we maintain consistency across the lineup, from the 46 Express to the 55 Walkaround.

Fishability-Driven Engineering

Infusion cutting weight for speed. It’s about dialing in the right balance, minimizing flex, keeping the center of gravity low, and delivering responsiveness under full load.

Each infused Walkaround and Gameboat is built to keep the cockpit clean, the ride dry, and the focus on the bite, not the pounding.

Owner-Operator Friendly

When hulls are properly balanced and stiff, they handle predictably, even for experienced owners without a full-time crew. Our infused builds are purpose-built for anglers stepping up from production platforms, looking for control, comfort, and serious capability.

This approach is especially evident in models like the 46 Walkaround, where performance and ease of use come together.

Is Resin Infusion Right for Your Next Build?

It leads to better handling, increased longevity, and fewer structural surprises down the road. That’s why we use it in every Release model, Gameboat, Walkaround, and Flybridge-Walkaround alike.

Infusion works because it eliminates the inconsistencies that undermine offshore builds. No shortcuts, only proven structure, engineered from the stringers up.

FAQ

The more you know about boatbuilding, the more questions you ask, and that’s exactly how it should be. Below are real concerns from serious anglers and buyers who want to understand how resin infusion impacts performance, reliability, and long-term ownership.

What’s the largest hull size that can be infused?

We’ve infused hulls up to our 66 Flybridge Gameboat. With proper tooling and controls, infusion scales effectively, even on multi-deck, offshore platforms.

Why do some builders still avoid resin infusion?

It comes down to commitment. Infusion requires precision, equipment, and build discipline. Some builders stick with hand lay-ups because it’s what they know. We use infusion because it produces better boats.

Does resin infusion affect warranty or insurance?

Positively. Infused hulls are more consistent and structurally stable, which is something insurers, surveyors, and future buyers recognize. Documentation is also easier when the process is controlled and repeatable.

Is an infused hull more prone to cracking?

No. Infusion improves resin distribution and laminate bonding, reducing stress risers that often cause cracking. When combined with high-quality core materials, it results in a hull that’s both strong and resilient.

Is Resin Infusion Overkill for Smaller Boats?

Not at all. In builds like our 36 Walkaround, infusion makes a big difference in ride quality, efficiency, and handling, especially when fully loaded. Smaller boats benefit more from structural precision per square foot than larger platforms do.

Can You DIY an Infused Hull?

Technically possible. Realistically?

Not practical. Achieving a stable vacuum, managing resin flow, and matching cure times across complex layups requires controlled environments and experienced teams. Precision matters too much offshore to gamble with improvisation.

How Can You Spot Poor-Quality Infusion?

Look for dry spots, voids, or uneven flow under the gelcoat. Ask about infused stringers, core materials, and whether vacuum records or flow diagrams exist. At Release, we infuse the hull, bulkheads, stringers, and deck, so strength is built in from day one.

Can You Repair an Infused Hull If It’s Damaged?

Yes. Infused laminates can be repaired when done by qualified technicians using compatible resin systems. Clean, controlled builds are often easier to repair than saturated, inconsistent lay-ups. We engineer for long-term durability, and when damage occurs, we make sure repairs are clean and structural.