Release Holiday Update

Our team is hard at work this holiday season steadily working on completing our 34,43 and 46 Walk Arounds. Below is a great photo of our 46 Walk Around with the Zeus PODS installed, our build out of the engine room, the deck ring cap and a nice shot of the complete deck being hoisted off of the mold. Our …

34 Stringer Grid

Our team has just completed installing the steel framing for constructing the 34 Stringer Grid. Our team will now continue construction on the first Release 34 and will shortly begin installing a completed stringer grid. Our stringer grid system allows our team to build a lighter, stronger and more rigid hull while allowing us to improve overall efficiency during the …

The 34′ Deck

The 34′ Deck-Liner Plug is well under way. Working on it every day from the plans of naval architect Erwin Gerards are three of Florida’s finest Master Plug Builders. Construction of this piece began earlier this week (week of June 26). Currently under the ownership of Release Boatworks, this vessel will play the role of our demo boat… keep an …

The Stringer System

In order to achieve a tight fit, the stringer system plug is being built in place. The wood fixtures will be covered in formica and a perfect mold will be made from them. The stringer grid will then be laminated on mold and will contain the complete writing and plumbing chases as well as the floors for an engine room and …

34′ Release — Takin’ Shape

After countless hours of deisgn, testing materials, prepping the surface, making inserts, and two weeks of “loading” the hull, it was finally time to infuse! We left the hull bagged and vacuum overnight, and the next morning we set up the hoses and the manifold system and opened the first valve… 46 minutes later, we had Hull#1 — and it …

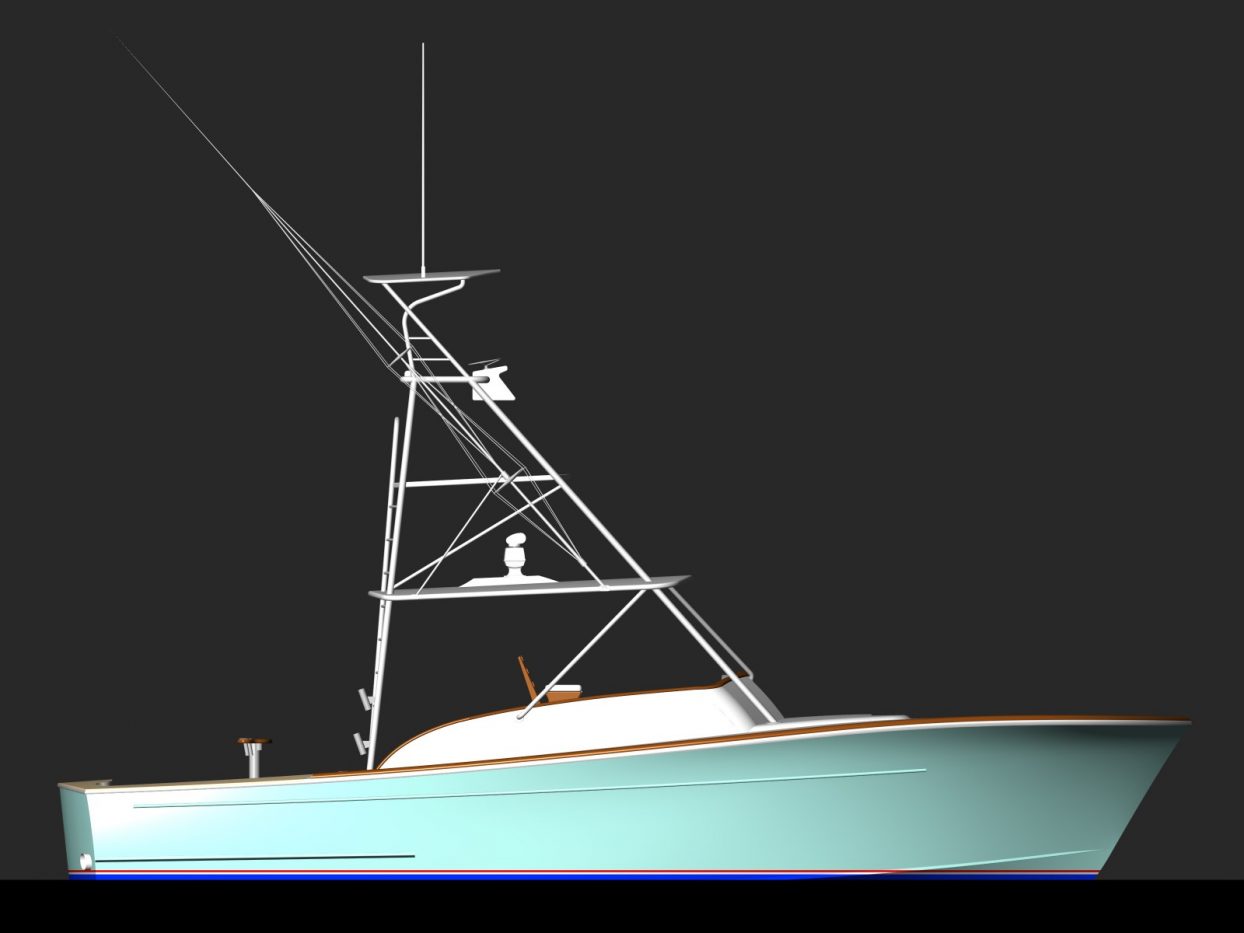

The Release 34

Once in a great while a boat comes along and for one reason or another becomes a classic. The 31 Bertram, the 36 Rybovich, the 43 Merritt are a few that come to mind. The Release 34 is such a boat. Based on the hull of the 34 Gamefisherman, a boat with legendary ride, handling and a nearly cult-like following. …